Electronic Rust Protection Experiment.

Sure, everyone’s heard of them, most interested parties have tried to find information online about them. We’ve read the forum posts, seen the testimonials and pictures of 4×4’s being driven on the beach and awed at the scientific theory behind them. Despite all this, we noticed an incredible lack of evidence these things actually worked. On the flip side, we saw a lot of forum posts from skeptics who swear these things do not work. We had the impression these people did not used or tried the technology before and was left wondering if these things actually worked.

This is the purpose of this blog: To prove or disprove the technology and put a silence to all the arguments with regards to Electronic Rust Protection technology.

So how are we going to run this blog? We’ll imagine this will be an ongoing project. This blog will be devoted to an experiment which we will document photographically on regular intervals. We will continue to document this experiment until I am satisfied I have given the technology given an adequate chance to prove or disprove itself.

Theory:

Rust is caused when iron reacts with oxygen to form a layer of iron oxide crystals. Definition of “Rust” from Wikipedia: “The rusting of iron is an electrochemical process that begins with the transfer of electrons from iron to oxygen. The rate of corrosion is affected by water and accelerated by electrolytes, as illustrated by the effects of road salt on the corrosion of automobiles.

The key reaction is the reduction of oxygen:

O2 + 4 e– + 2 H2O → 4 OH–

Because it forms hydroxide ions, this process is strongly affected by the presence of acid. Indeed, the corrosion of most metals by oxygen is accelerated at low pH. Providing the electrons for the above reaction is the oxidation of iron that may be described as follows:

Fe → Fe2+ + 2 e−

The following redox reaction also occurs in the presence of water and is crucial to the formation of rust:

4 Fe2+ + O2 → 4 Fe3+ + 2 O2−

Additionally, the following multistep acid-base reactions affect the course of rust formation:

Fe2+ + 2 H2O ⇌ Fe(OH)2 + 2 H+

Fe3+ + 3 H2O ⇌ Fe(OH)3 + 3 H+

as do the following dehydration equilibria:

Fe(OH)2 ⇌ FeO + H2O

Fe(OH)3 ⇌ FeO(OH) + H2O

2 FeO(OH) ⇌ Fe2O3 + H2O

From the above equations, it is also seen that the corrosion products are dictated by the availability of water and oxygen. With limited dissolved oxygen, iron(II)- containing materials are favoured, including FeO and black lodestone (Fe3O4). High oxygen concentrations favour ferric materials with the nominal formulae Fe(OH)3-xOx/2. The nature of rust changes with time, reflecting the slow rates of the reactions of solids.

Furthermore, these complex processes are affected by the presence of other ions, such as Ca2+, which both serve as an electrolyte, and thus accelerate rust formation, or combine with the hydroxides and oxides of iron to precipitate a variety of Ca-Fe-O-OH species.”

So how does Electronic Rust Protection Work?

We really did try to find a single consensus on how these things are supposed to work. We read all sorts of stories about how they turn cars into capacitors, tricking nature, blasting with electrons at high voltage etc. etc. Basically the general consensus is they turn your car into a capacitor and somehow this is supposed to retard rust. We are not after scientific explanation.We seriously doubt anyone knows how these things actually work which lead us to be sceptical about the technology. That is why we are doing this experiment with real unit.

Experiment

Instruments used:

2x Cast Iron Pans

2x Cotton Cloths

1x Car Battery

1x GroundWire

1x Bag of Sea Salt

1x Dishwasher

1x Dishwashing powder

1x Auto Rust Warrior unit.

Theory:

Cast Iron is incredibly prone to rust. Installing a Rust Warrior Protection Moduleto one of the cast iron pans should minimize rust from “growing” on the pan.

Technique:

- Take 2 cast iron pans. Clean the pans thoroughly with wire brush to remove any surface protectant (conditioner) from both pans.

- Place pans in dishwasher and run through full cycle with dishwashing powder to remove any excess protectant from pans.

- Remove rust from both pans after dishwashing with wire brush.

- Rinse and dry both pans thoroughly with cotton cloth (new cloth for each pan)

- Bathe both units pans in a saturated solution of salt water (More salt than will dissolve in the water).

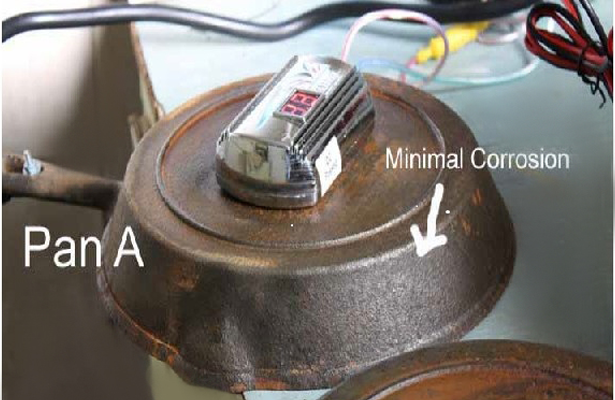

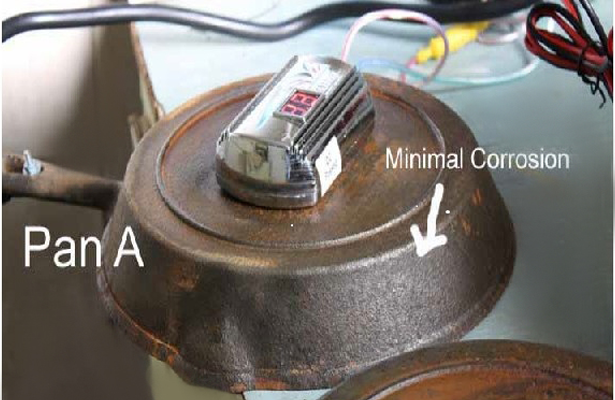

- Install Auto Rust Module device to one of the pans (Pan A).

- Connect earth wire from negative pole of car battery to Pan A. This should simulate the way a car battery is connected to the chassis of a car.

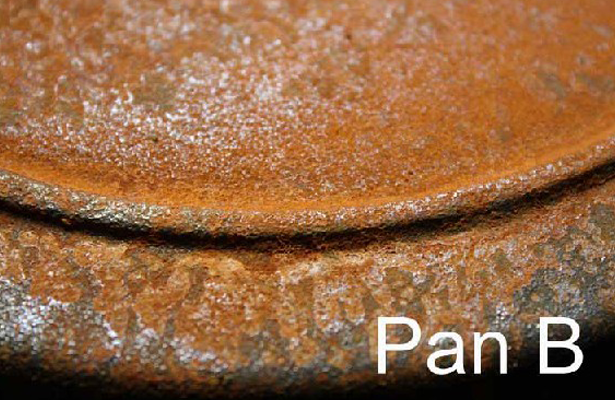

- Leave Pan B without any rust protection device or negative earth.

- Move both devices to a cool environment.

- Observe results, take photographs of changes to both pans and compare results over time.ron pans should minimize rust from “growing” on the pan.

Results:

Day 5

Rust is evident on both pans. However the Pan B appears to have a higher concentration of rust. See images below.

Day 5

Rust is evident on both pans. However the Pan B appears to have a higher concentration of rust. See images below.

Day 10

Again observed rust on both pans, again Pan B appears to have less rust evident. Pan A appears to have an area on top of which no rust is evident. Pan A also appears to have less rust evident on sides. See pictures below.

Day 20

Rust beginning to cake on Pan B, rust pitting observed as well as large rust crystals on Pan B. Rust is sparser and more dappled on Pan A

Day 20

Rust beginning to cake on Pan B, rust pitting observed as well as large rust crystals on Pan B. Rust is sparser and more dappled on Pan A

Rust beginning to cake on Pan B, rust pitting observed as well as large rust crystals on Pan B. Rust is sparser and more dappled on Pan A.

Day 30

Rust and crystallizationkeep appearing on Pan B. Pan A appears to have thinner, more localized rust to certain locations around pan. Evidence displayed of most significant rust spots.

Day 30

Rust and crystallizationkeep appearing on Pan B. Pan A appears to have thinner, more localized rust to certain locations around pan. Evidence displayed of most significant rust spots.

Further, notice the “Rim” of pan a exhibits no or very little rust, while the rim of Pan B is completely covered. Also notice a large crystal of rust on Pan B in the centre of the first image.

Conclusion

There is no doubt the Electronic rust protection module was effective in minimizing the rust on Pan A. Although pan A did rust significantly, this occurred at the quarter speed of Pan B. We also noticed that Pan A did not rust as heavily as on Pan B where some caking and crystallization was evident towards the end of the experiment. A number of factors could be improved upon in the experiment. Firstly, pans are not cars. Secondly a controlled environment would not doubt help improve the accuracy of this test. Also the manufacturer claims the paint on a car acts as a dielectric which is supposed to create the capacitive coupler effect. Our pans had no paint what so ever. Initial results however definitely infavor the Electronic Rust Protection technology.

WHAT IS RUST? WHY DOES IT APPEAR ON YOUR CAR?

Rust is an electrochemical process that takes place whenever bare metal is exposed to air moisture or water. Due to excessive exposure of your vehicle to these conditions corrosion starts to appear on your car. This process is driven by loss of negative electrons from within your vehicle’s metal.

HOW DOES SUPERIOR RUST PROOFING MODULE STOP CORROSION PROCESS?

Superior Rust Proofing Module generates a contentious flow of negative charges to entire structure of your vehicle (including frame, inner and outer panels) and stops corrosion process.

SEE HOW IT WORKS

Despite cars lasting longer and longer these days, an automotive service technician will notice that people often resell their car after around five years, in order to buy a newer model.

Testimonials

It’s hard to find anything unsatisfactory about our high quality products.

REX WATSON

We’ve used Superior Rustproofing on many vehicles int the past. We have been extremely thrilled with the results!

CASSIE VENTURA

Superior Rustproofing has exceeded our expectations when it comes to rustproofing. We highly recommend this product to all our families and friends.

BARNEY SMITH

We’ve used the Superior Rustproofing system in all of our vehicles. The installation is simple and can be moved between multiple vehicles.